We manufacture high-value, prefabricated modules from demanding wet units for shipbuilding to complex modules for industrial and construction projects. With full in-house capability, we deliver factory-finished modules that fit precisely, install quickly, and cut on-site time and risk.

Module manufacturing requires a mix of engineering precision, craftsmanship and logistics. At Hermann’s we combine all three:

Our approach guarantees consistent quality, reliable delivery and cost efficiency, even on the most complex projects. Hermann’s has a skilled design department and in-house, high-quality manufacturing capabilities, allowing us to deliver precisely what our customers want.

Refined work steps ensure a high-quality and repeatable module

Design & engineering — BIM / 3D CAD driven module design, clash-free interfaces, and manufacturing drawings ready for production.

Production & joinery — factory assembly of structural and interior components with marine-grade workmanship.

MEP integration — complete plumbing, HVAC and electrical fit-out performed in controlled conditions.

Test assembly & factory acceptance — full dry-run and leak/pressure/electrical tests before packing.

Packaging & logistics — bespoke transportation and lifting solutions to protect modules en route and ensure smooth installation.

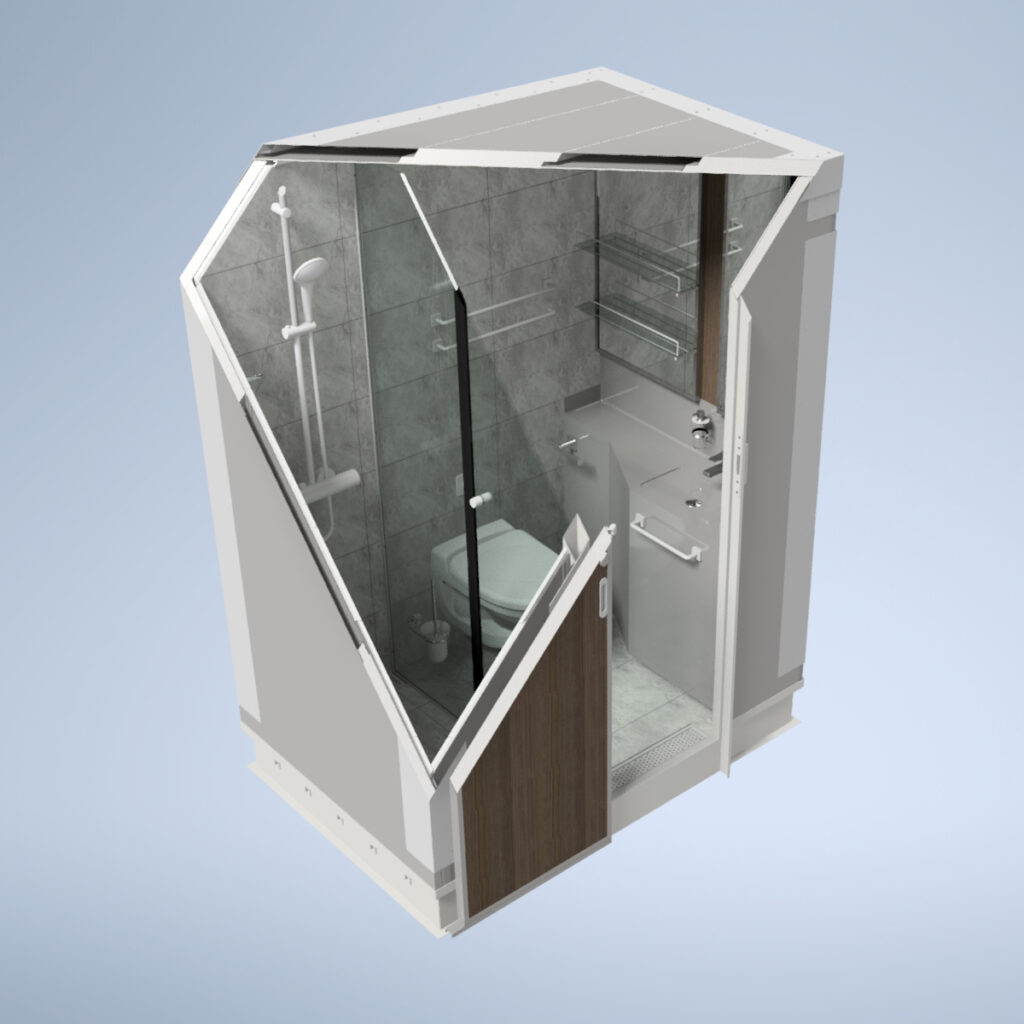

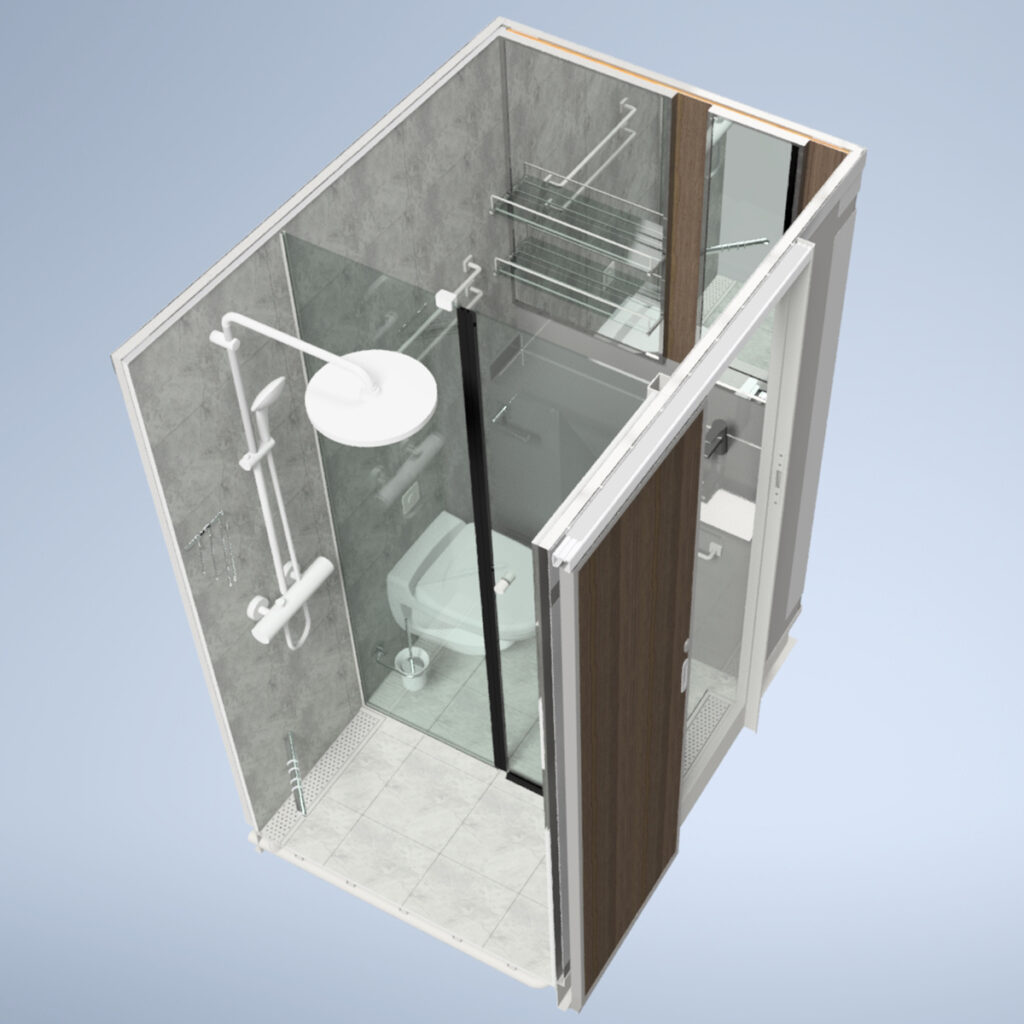

Reference: Pre-Assembled Wet Units For an Efficient Refit Project in France

The refit project of Norwegian Cruise Line’s Epic in Marseille required a fast and high-quality solution for renewing the vessel’s wet areas. Hermann’s met this need by delivering pre-designed wet units ready for installation on board. The modules were manufactured in Raisio and shipped in flatpack form directly to the site.

We manufacture the modules in our own modern production facilities

Our production is organized into dedicated woodwork, metalwork, and module manufacturing departments, along with a state-of-the-art paint shop. Our modern 5,000 m² production plant is located in Raisio, Finland, with excellent transport connections near the Meyer Turku shipyard.

We employ skilled professionals from a range of disciplines, committed to delivering high-quality solutions tailored to our clients’ needs. Thanks to our in-house production capabilities and trusted partner network, we can carry out complex projects from initial concept to finished product with reliability and precision.

In-house Engineering and Design Team

Hermann’s has deep expertise in marine interior design. We understand the industry’s specific technical and aesthetic requirements and integrate them seamlessly into every stage of our work. No project is too complex, we deliver complete design packages efficiently and on schedule.

Our in-house engineering team combines professionals with broad, hands-on experience across shipbuilding and interior outfitting. Their practical insight ensures that every plan is both innovative and buildable, turning concepts into fully realized solutions that meet the highest standards of the marine industry.

it’s all about attitude – strive for the impossible, dare to demand, and prepare to get it

Let’s make it real

From plan to production – we are here to help! Don’t hesitate to contact us. We are happy to answer any questions you may have.

Mr. KARO KYMÄLÄINEN

Sales manager

karo.kymalainen@hermanns.fi

+358 44 970 4530