Introduction

Our passion is to appreciate, identify and implement the customer’s needs to high-quality design output. In order to achieve this, we understand the characteristics features of the materials, the expedient production methods and the challenges and constraints of the real world. Challenges make us ignite and overcoming them using cutting-edge technology, swarm intelligence and being forced to think outside of the box is what keeps the fire burning!

Engineering & Product Design

Hermann’s special expertise is challenging interior design works for the marine industry and we have both understanding and know how to apply industry-specific requirements in all of our operations in this area. Even the most demanding assignments are not a problem for us and we are able to deliver on a comprehensive basis all the plans our customers need efficiently and on time. As our customer, you have access to a wide range of in-house design expertise; our design team is made up of people from diverse working backgrounds with hands-on experience to ensure that the plans come to fruition in real life as well.

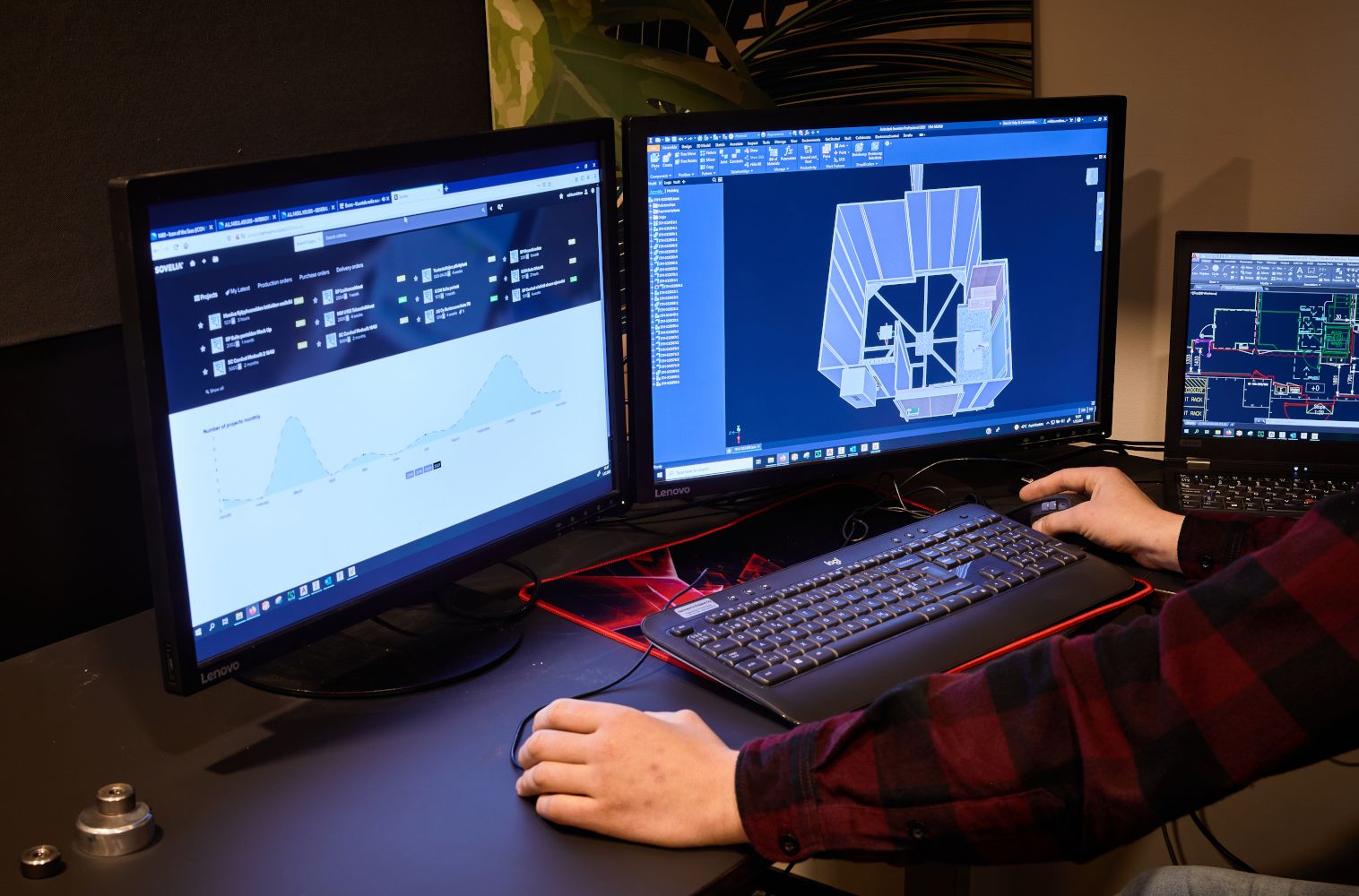

Product Life Cycle Management (PLM)

Our design philosophy is based on and takes into account product lifecycle management at all stages of its development process, which can be divided into three areas: communicate, manage and collaborate. None of the above phases should be considered as isolated. In reality, a project does not run sequentially or separated from other product development projects, with information flowing between different people and systems. A major part of PLM is the coordination and management of product definition data. This includes managing engineering changes and release status of components; configuration product variations; document management; planning project resources as well as timescale and risk assessment.

After all everything we do is about the information, knowledge and awareness that make up the data we use together. This data is made up of different streams and often small details as well as small grains of information and losing any part of that can be devastating. We take the knowledge we receive seriously and nurture it by storing and managing it in the way it deserves: Over the years, we have built and developed an unique system for product data and lifecycle management in project operations. This is how the data of all our customers is stored, secured and kept in order.

Visualization

One of our specialties is product visualization, which includes technologies such as DMU (digital mock-up), immersive virtual digital twin (virtual reality) as well as photorealistic imaging and real time rendering.

We believe that even the most complex things do not have to be laborious to understand and internalize if they are presented in a human way: in fact, when carefully considered, the world in which we live is largely multidimensional. So why not present things as they really appear? By visualizing information we make it easier to our customers to perceive complex entities and thus focus energy on the essential; to create and develop something new and aesthetic because we are not machines but people and that is what we know the best.

Analysis & Simulation (FEA)

Workflow & project simulation (4D & 5D simulation)

Hermann’s has a a comprehensive project review solution that supports coordination, analysis, and communication of design intent and constructability. With the help of ex ante evaluation, we can ensure the smooth running of the project from start to finish and thus achieve significant cost savings.

Project simulation is used to analyze real projects. The goal of the simulation is to show the different possible outcomes of made decisions, along with the probability that each outcome will occur. The simulation helps in reducing the project risk and in choosing the best project plan. The project is first modeled along with uncertain variables. A simulation is then run to check the different possible outcomes and their probability as a result of different inputs for the uncertain variables.

Finite element analysis

Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow and other physical effects. Finite element analysis shows whether a product will break, wear out, or work the way it was designed. It is called analysis, but in the product development process, it is used to predict what is going to happen when the product is used.

FEA works by breaking down a real object into a large number (thousands to hundreds of thousands) of finite elements, such as little cubes. Mathematical equations help predict the behavior of each element. A computer then adds up all the individual behaviors to predict the behavior of the actual object.

Information modeling (BIM & Virtual twin)

Building Information Modeling (BIM) is the holistic process of creating and managing information for a built asset. Based on an intelligent model and enabled by a cloud platform, BIM integrates structured, multi-disciplinary data to produce a digital representation of an asset across its lifecycle, from planning and engineering to construction and operations.

Using the information-rich models created with BIM, our designers, production workers and construction teams can collaborate to make more-informed decisions earlier in the design process to deliver projects more efficiently. Any design changes made in BIM models are automatically updated throughout the model, keeping designs and documentation coordinated and more reliable.

Introduction

Our passion is to appreciate, identify and implement the customer’s needs to high-quality design output. In order to achieve this, we understand the characteristics features of the materials, the expedient production methods and the challenges and constraints of the real world. Challenges make us ignite and overcoming them using cutting-edge technology, swarm intelligence and being forced to think outside of the box is what keeps the fire burning!

Engineering & Product Design

Hermann’s special expertise is challenging interior design works for the marine industry and we have both understanding and know how to apply industry-specific requirements in all of our operations in this area. Even the most demanding assignments are not a problem for us and we are able to deliver on a comprehensive basis all the plans our customers need efficiently and on time. As our customer, you have access to a wide range of in-house design expertise; our design team is made up of people from diverse working backgrounds with hands-on experience to ensure that the plans come to fruition in real life as well.

Product Life Cycle Management (PLM)

Our design philosophy is based on and takes into account product lifecycle management at all stages of its development process, which can be divided into three areas: communicate, manage and collaborate. None of the above phases should be considered as isolated. In reality, a project does not run sequentially or separated from other product development projects, with information flowing between different people and systems. A major part of PLM is the coordination and management of product definition data. This includes managing engineering changes and release status of components; configuration product variations; document management; planning project resources as well as timescale and risk assessment.

After all everything we do is about the information, knowledge and awareness that make up the data we use together. This data is made up of different streams and often small details as well as small grains of information and losing any part of that can be devastating. We take the knowledge we receive seriously and nurture it by storing and managing it in the way it deserves: Over the years, we have built and developed an unique system for product data and lifecycle management in project operations. This is how the data of all our customers is stored, secured and kept in order.

Visualization

One of our specialties is product visualization, which includes technologies such as DMU (digital mock-up), immersive virtual digital twin (virtual reality) as well as photorealistic imaging and real time rendering.

We believe that even the most complex things do not have to be laborious to understand and internalize if they are presented in a human way: in fact, when carefully considered, the world in which we live is largely multidimensional. So why not present things as they really appear? By visualizing information we make it easier to our customers to perceive complex entities and thus focus energy on the essential; to create and develop something new and aesthetic because we are not machines but people and that is what we know the best.

Analysis & Simulation (FEA)

Workflow & project simulation (4D & 5D simulation)

Hermann’s has a a comprehensive project review solution that supports coordination, analysis, and communication of design intent and constructability. With the help of ex ante evaluation, we can ensure the smooth running of the project from start to finish and thus achieve significant cost savings.

Project simulation is used to analyze real projects. The goal of the simulation is to show the different possible outcomes of made decisions, along with the probability that each outcome will occur. The simulation helps in reducing the project risk and in choosing the best project plan. The project is first modeled along with uncertain variables. A simulation is then run to check the different possible outcomes and their probability as a result of different inputs for the uncertain variables.

Finite element analysis

Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow and other physical effects. Finite element analysis shows whether a product will break, wear out, or work the way it was designed. It is called analysis, but in the product development process, it is used to predict what is going to happen when the product is used.

FEA works by breaking down a real object into a large number (thousands to hundreds of thousands) of finite elements, such as little cubes. Mathematical equations help predict the behavior of each element. A computer then adds up all the individual behaviors to predict the behavior of the actual object.

Information modeling (BIM & Virtual twin)

Building Information Modeling (BIM) is the holistic process of creating and managing information for a built asset. Based on an intelligent model and enabled by a cloud platform, BIM integrates structured, multi-disciplinary data to produce a digital representation of an asset across its lifecycle, from planning and engineering to construction and operations.

Using the information-rich models created with BIM, our designers, production workers and construction teams can collaborate to make more-informed decisions earlier in the design process to deliver projects more efficiently. Any design changes made in BIM models are automatically updated throughout the model, keeping designs and documentation coordinated and more reliable.