Pre-Assembled Wet Units For an Efficient Refit Project in France

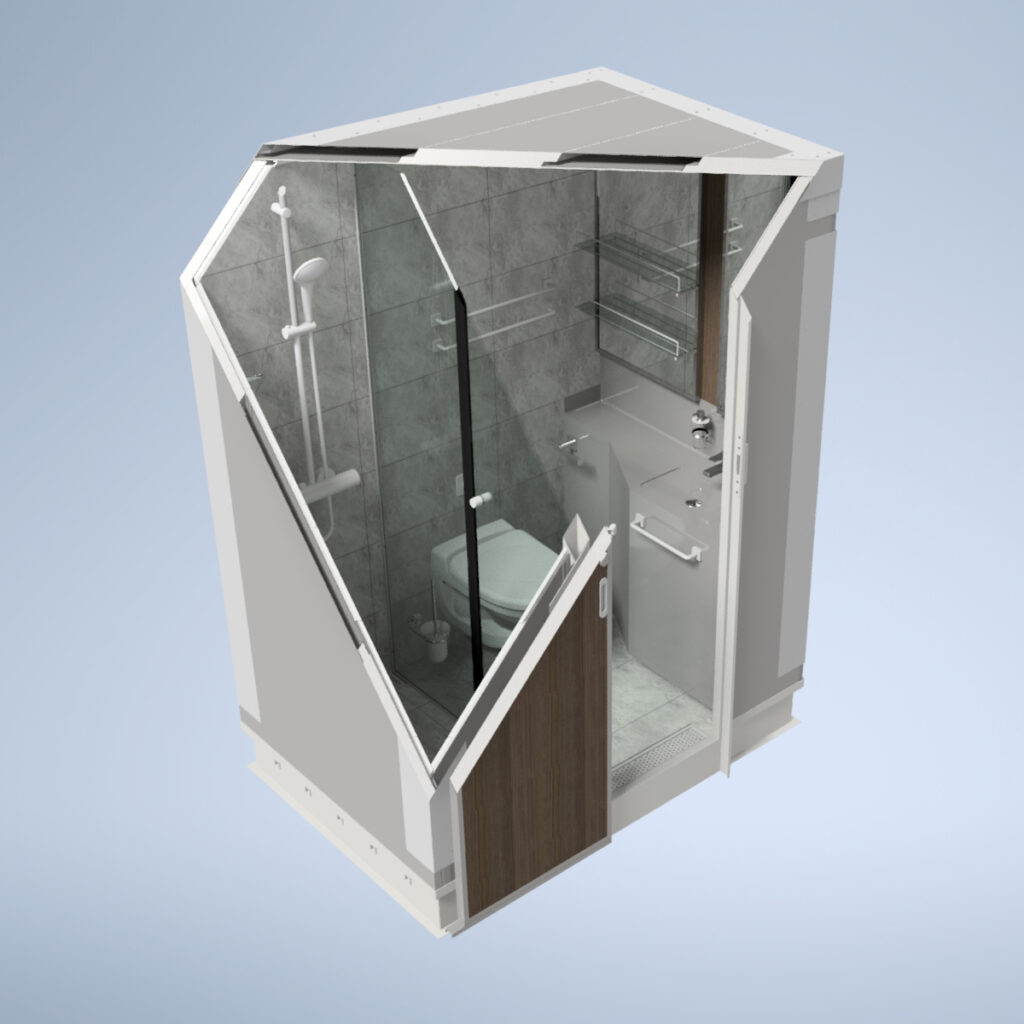

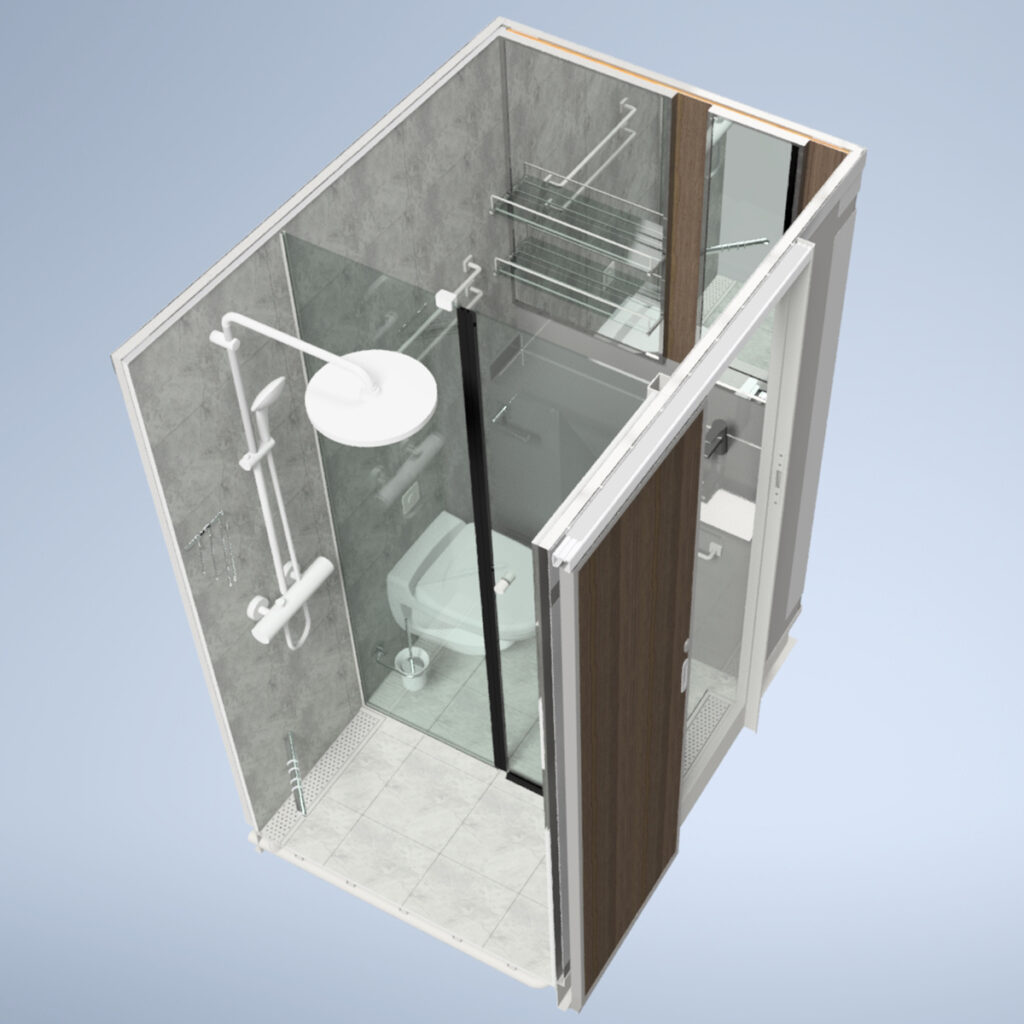

The refit project of Norwegian Cruise Line’s Epic in Marseille required a fast and high-quality solution for renewing the vessel’s wet areas. Hermann’s met this need by delivering pre-designed wet units ready for installation on board. The modules were manufactured in Raisio and shipped in flatpack form directly to the site.

Speed, quality, and efficiency to meet the refit schedule

This was a demanding project with a tight schedule, where smooth installation and high manufacturing quality were key. Hermann’s solution relied on precise pre-engineering and thorough preparation, enabling quick and error-free installation on board without extra adjustments or delays.

Production in Raisio – precise design enabled smooth installation in Marseille

All wet units were manufactured at Hermann’s own production facility in Raisio. Accurate 3D design ensured the modules were built to exact measurements, eliminating the need for adjustments on site. One module was pre-assembled at the factory to verify quality and structural functionality. After this, all units were packed in flatback form and delivered to Marseille, where they were assembled efficiently according to the plans.

Technical details

- Client: Kaefer Oy

- Shipowner: Norwegian Cruise Line

- Vessel: Epic

- Project: Refit, Marseille, France

- Product: Wet units

- Manufacturing Site: Hermann’s, Raisio, Finland

- Delivery method: Precise 3D design → pre-assembly of one unit → flatback delivery → assembly on site